- Home

- Profile of Sampu

- Garage type

- Classic cases

- Manufacturing strength

- News and information

- Contact us

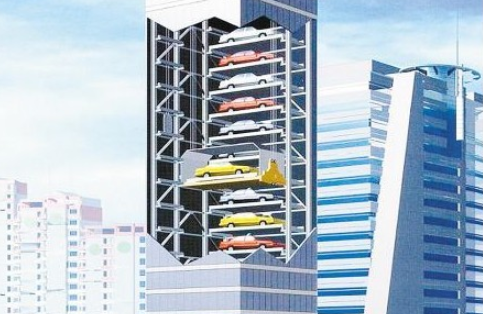

There is a rotatable tray installed at the bottom of the garage, and the tray structure is comb fork type. The comb fork on the tray is staggered with the comb fork on the lift fork, so that the lift fork can travel up and down on the tray. The stereo garage manufacturer said that when the garage is not working, the lift fork is located below the tray. The body steel structure system, lifting system (lift fork), lateral movement system, rotating tray system, high-speed rolling door system, electrical control system, and fire safety control system can all contribute to the operation.

1. First, drive the car onto the tray.

The front comb fork of the tray is made in an arc shape, which matches the car wheel. A photoelectric sensor is installed between them. When the front wheel of the car enters the arc-shaped comb fork, the sensor detects the signal of the car and sends out a position alarm signal, reminding the car driver that the car is in place. After the driver locks the engine and walks out of the garage, the garage administrator starts the automatic operation program of the garage. The electric high-speed rolling garage door quickly closes, separating the inside of the garage from the outside. The lift fork under the tray runs upward, passes through the tray, and the comb forks on the lift fork lift the car up the central shaft of the garage to the parking level to be parked.

2. Lateral movement

Each parking level is symmetrically divided into two parking spaces by the central lift fork running shaft. Each parking space has a horizontal movement bracket, which can move left and right under the drive of friction wheels. The horizontal movement bracket is also of comb fork structure, and the comb fork on it is staggered with the comb fork on the lift fork. There are travel switches and mechanical limit blocks installed on the support of the horizontal movement bracket in the shaft, which can effectively ensure that the horizontal movement bracket smoothly stops at the design position when it moves into the shaft. After the lift fork arrives at the parking level to be parked and stops slightly above the position of the horizontal movement bracket, the horizontal movement bracket moves from the parking space to the designed position in the shaft. The lift fork runs downward, passes through the horizontal movement bracket, and the car is placed on the horizontal movement bracket. The lift fork continues to run back to the starting position, while the horizontal movement bracket moves back to the parking space under the drive of the friction wheels, completing a parking operation process.

The stereo garage manufacturer said that when it is necessary to take the car, first move the horizontal movement bracket where the car is parked to the middle shaft. The lift fork runs from the bottom to the top, passes through the horizontal movement bracket, and places the car on the lift fork, stopping slightly above the horizontal movement bracket. After the horizontal movement bracket moves back from the shaft to the parking space, the lift fork with the car runs downward, passes through the bottom rotating tray, and places the car on the rotating tray, while the lift fork continues to run back to the starting position. The rotating tray rotates with the car, positioning the car cabin in front of the garage door. After opening the garage door, the driver can enter the car and drive it out.